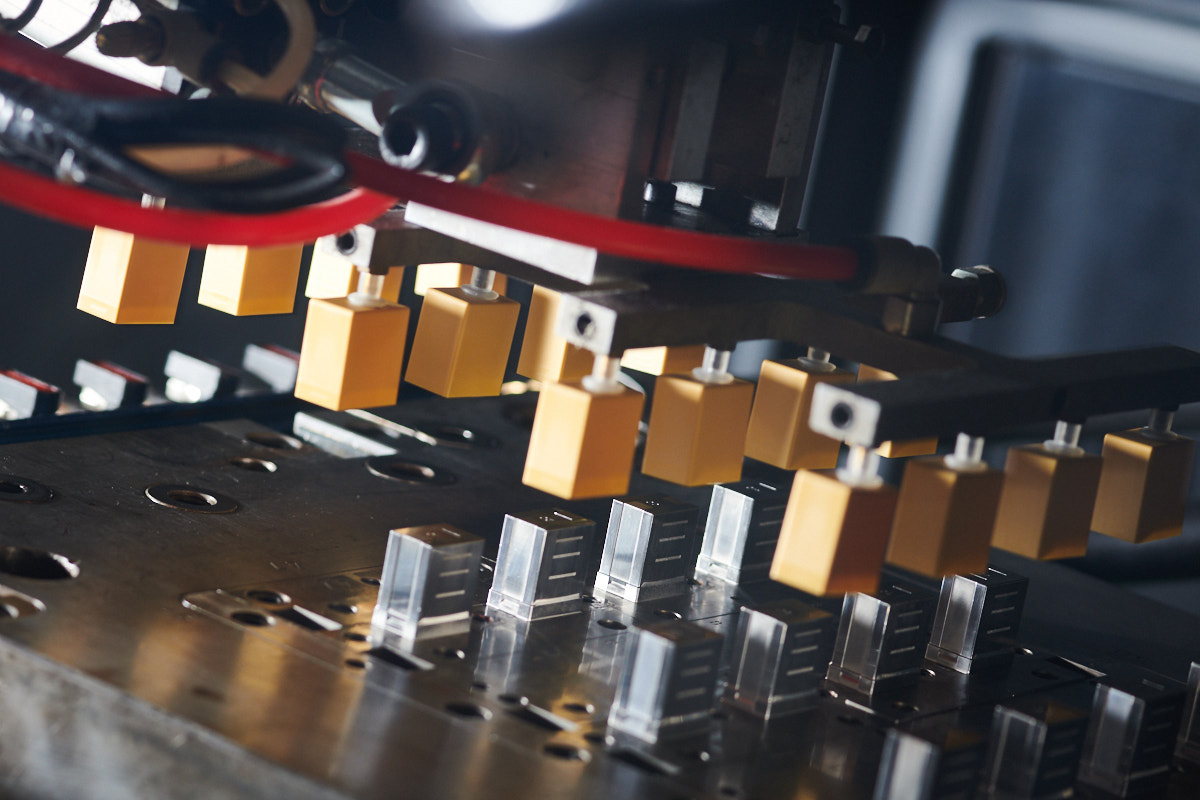

Molding Plastic Components

We carry out molding of plastic material with cutting-edge technologies, managed with "lean manufacturing" processes and coordinated by an "Industry 4.0" computer system for the collection of production data necessary for the management of performance that allow us to guarantee products that meet the various quality standards and within the agreed times.

After carefully verifying the molds, raw materials and product and process documentation, we take care of the molding:

Thermosetting Molding

Our thermosetting molding departments consist of 2 injection molding machines from 130 to 175 t, from 01 compression press up to 450 t., from 2 injection molding machines from 270 to 300 t.

Thermoplastic Molding

Our thermoplastic molding departments consist of n 22 injection molding machines up to 450 t. , 1 Bi-injection of 200 t. , n 2 presses in clean room.

Iml Molding

The IML system allows us to customize the product during pressing, with 2D and 3D shapes with no type of restriction from a graphic point of view. Our machines can print in single or double layer for In Mould Labelling (IML) or in Mould Decoration (IMD) on any type of printable plastic material: polypropylene, polyethylene, polycarbonate, polystyrene, methacrylate, polyester.

Do you want to develop a project together with our professionals?

Contact technical support:

Stefano Corsetti

Manufacturing Engineering Manager