Ensuring performance

Each mold has its own history, through our program "MOULD LIFETIME VALUE" we monitor its performance from its design to the number of strokes made and maintenance interventions, we know how and where to intervene to ensure maximum efficiency in production and extend its production life in order to obtain a greater economic advantage.

Maintenance, Modifications and Spare Parts

We are organized to guarantee an ordinary and extraordinary maintenance and assistance service. We assist you for any problem, intervening directly at your plant for its resolution.

We offer our customers a scheduled plan of overhaul and maintenance, with a variable periodicity depending on the production needs and the historicity of the mold, our program includes: the return to the company, disassembly and complete vision, issue of a report for damaged or worn parts, generation of a cost estimate for maintenance and repair to acceptance are replaced the worn parts and carried out repairs realizing where laser welding is also required.

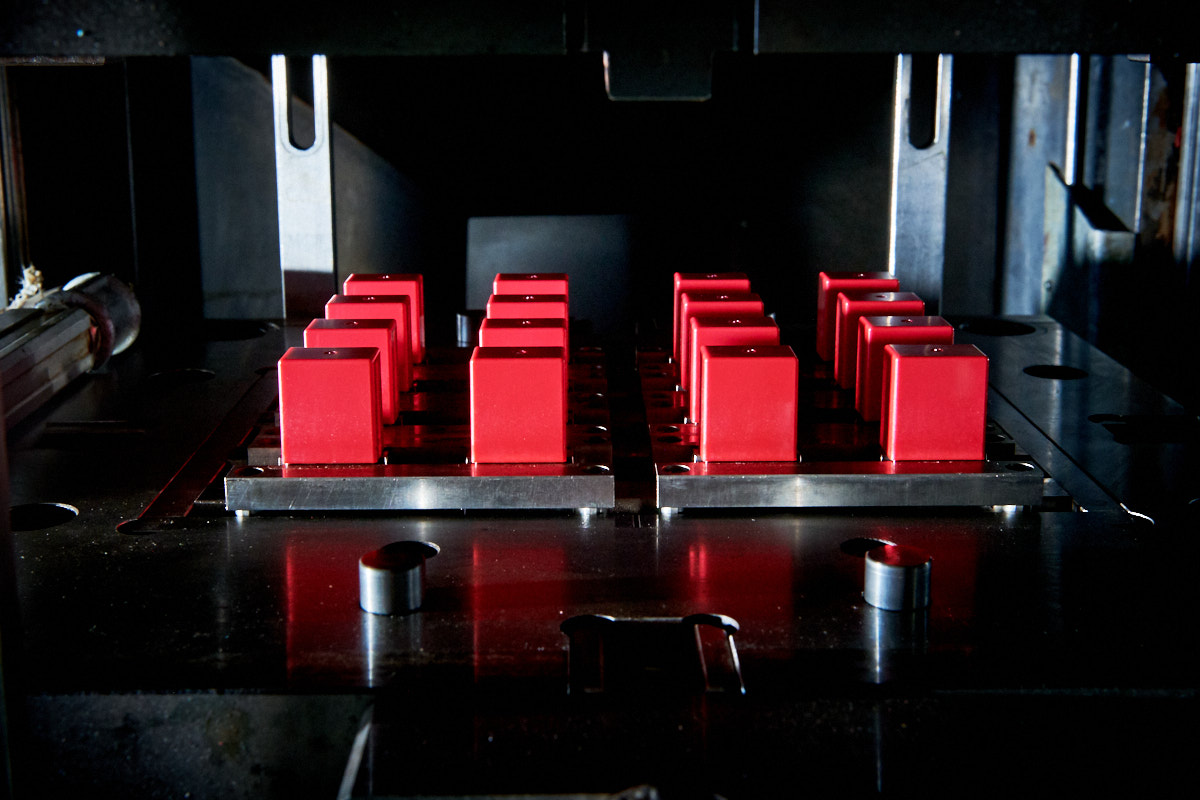

Pre-Series Production

We have the ability to carry out pre-series productions or small batches to allow our customers to minimize the time-to-market of their products.

Assembly

We are able to create a precise and monitored assembly service, ensuring regularity and punctuality in deliveries, all thanks to expert hands assisted by procedures and process automation.

Do you want to develop a project together with our professionals?

Contact technical support: